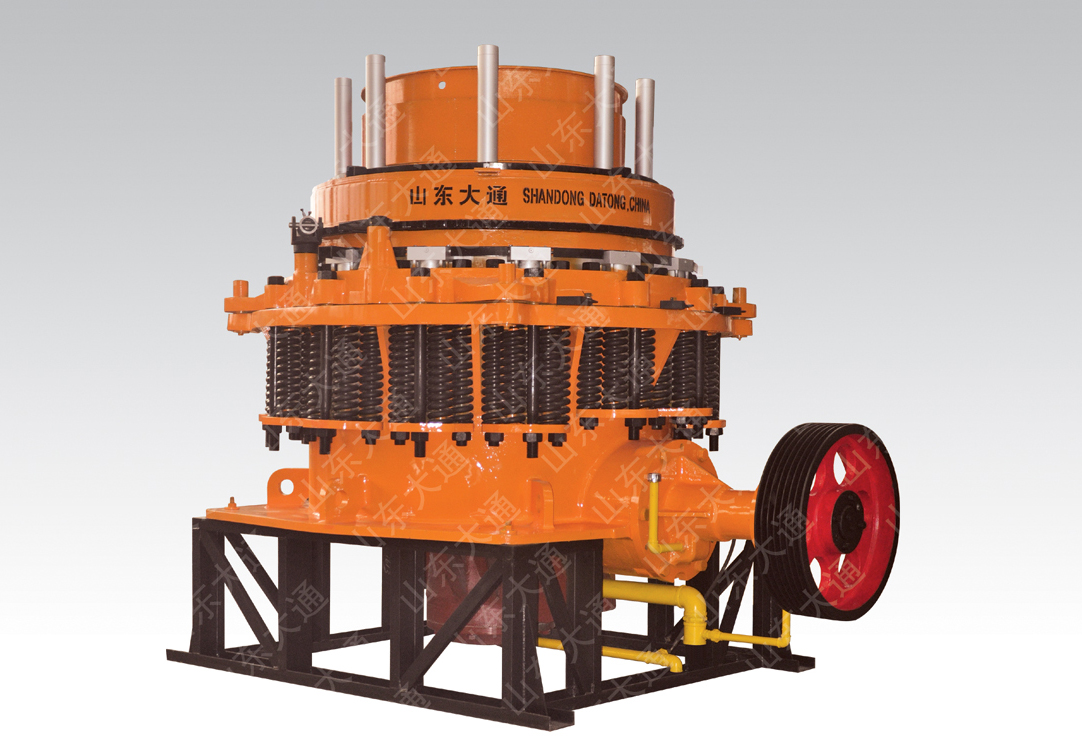

The cone crusher is widely used in the crushing industry due to its high cost performance. However, through the company's return visit and patrol inspection to customers, it is found that users lack the understanding of maintenance in the process of using the crusher. Now, the precautions for maintenance of the cone crusher are listed as follows:

The maintenance of the crusher is divided into large, medium and small maintenance. The maintenance process must be carried out regularly according to the reasonable maintenance time of the equipment, and fatigue operation must be avoided.

1、 Minor maintenance

The small maintenance includes:

1. Check the integrity of spherical tile, if there is damage, repair or replace it;

2. Check the wear condition of large and small cone wheels, and replace the ones with excessive wear in time;

3. Repair and check all kinds of kits, such as eccentric shaft sleeve, taper sleeve and straight sleeve;

4. Repair the threads of adjusting ring and supporting ring;

5. Change all kinds of lubricating oil regularly;

Each minor repair of the above items may not be carried out completely, which shall be selected according to the actual situation

2、 Medium maintenance

1. Replace the large and small bevel gears in time;

2. Replace the transmission bearing and spherical bearing in the cone crusher;

3. Check the clearance between the spherical bearing seat of cone crusher and the upper end face of eccentric shaft sleeve;

4. Check the wear of the spherical bearing seat and the body, and the matching part of the cone and the main shaft of the cone crusher, and replace it if necessary.

3、 Overhaul and maintenance

Overhaul and maintenance are recommended to be carried out once a year.

1 including all contents of medium maintenance;

2. Disassembly, inspection, measurement, repair or replacement of all parts;

3 check, repair or replace the adjusting ring, supporting ring, spring and spring bolt;

4. Calibrate the technical performance of the whole crusher, and carry out technical transformation according to the specific situation

There are two ways to work out the maintenance cycle: one is to determine how many tons of ore to be crushed; the other is to determine how long to operate according to the load. Only taking effective maintenance measures can make the equipment operate normally and reduce unnecessary shutdown loss.

簡體中文(wén)

簡體中文(wén)